Rose Gong PhD project profile

Optimizing Automotive Assemblies with Flexible Roll Formed and Cast Parts

Researcher: Jie Gong

Aim:

The outcome of this project will investigate a method to optimize flexible roll formed and casting structure to conduct the light-weight design and improve the mechanical performance.

Background:

Lightweighting is a concept in the automotive industry, which aims to improve the vehicle performance and fuel efficiency but not to compromise the functionality. As automotive body structure occupies a large proportion of overall mass and has a vital relationship with safety, reducing the mass of automotive body structure is widely investigated. As light material with high strength becomes to be used, challenges have been arisen for conventional manufacturing technology like stamping. To solve this, as flexible roll forming (FRF) can also produces channels with variable cross section, this technology is started to be used in automotive industry. This study will use the structural optimization method to achieve the aim of weight reduction and improve the structural performance of the flexible roll formed front rail and rocker panel assembly.

Methodology:

The thin-wall channels manufactured by FRF can be optimized using shape optimization. To ensure that the optimized structure is defect free, the manufacturing constraints of FRF will be integrated into the optimization process. For casting joints, topology optimization will be selected as the method, and casting constraints will be considered as well. Experiments will be conducted to validate the optimized results.

Key Findings to date:

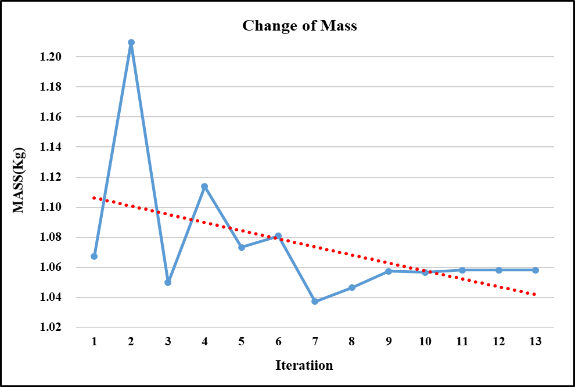

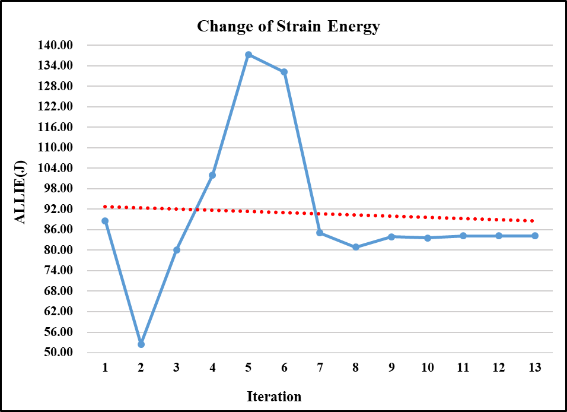

Linear channel (cross section with flat web but variable width) formed by FRF has been established by ABAQUS built-in python. Deterministic optimization algorithm was selected to accelerate the optimization process by calculating the sensitivity to find the descent direction. Manufacturing constraints have been integrated into the optimization to ensure the components that can be manufactured. The optimized results can be achieved (Figure 1).

Figure 1 shows that the optimized structure has a decrease both in mass and strain energy, which means the mechanical performance (stiffness) has been improved after optimization.

Future Work:

- Optimizing flexible roll formed component with variable width and depth under FRF manufacturing constraints.

- Optimizing assemblies that consist of complex channels connected by casting solid joints with manufacturing constraints.

Contact:

Jie Gong

Institute for Frontier Materials (IFM)

Deakin University, Geelong

Email: [email protected]