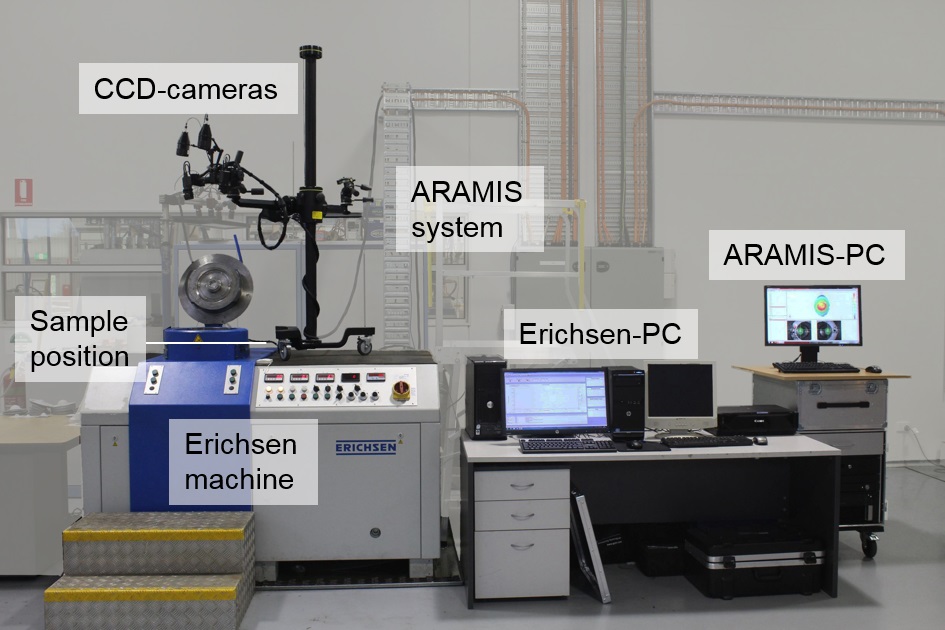

Our group has been conducting metal forming related research for more than 10 years and has produced some outstanding results across numerous problems for our domestic and international industry partners. We have a number of facilities that allow us to perform experiments and prototyping studies as well as finite element analysis and advanced material characterisation.