News

June 2024

SMF group researchers awarded $4.9 million in ARC Industrial Transformation Training Centres grant

ARC Training Centre for Resource Efficient Alloys in a Circular Economy. To reduce carbon emissions in the alloy sector, we need both low energy solutions and increased recycling. This Centre aims to create leaders in alloy innovation for a more circular economy. Leadership will be developed on-the-job via four strategic objectives: USE-LESS – develop alloys and structures that use less mass for the task; DEMAND-LESS – innovate in alloy and process design to create lower energy pathways; LAST-LONGER – create alloying solutions that facilitate component longevity, and RE-USE – design new alloys, processes and components that facilitate recycling and re-use. Outcomes will include new alloys, products and processes. Benefits will include reduced emissions and increased competitiveness of Australian enterprises.

September 2022

New publication on manufacture of long steel components that are reinforced with a carbon fibre patch (CFRMH) via roll forming: PhD student Xinyu (Ivan) Hu et al. recently publish the work on roll-forming CFRMH sheets. The material deformation after roll forming and the failure modes after the structural tests are analysed with optical microscopy.

The results of this study show that part quality and forming defects after roll forming depend on the carbon fibre orientation and the forming temperature. Depending on the carbon fibre layup, an increase in specific energy absorption of more than 45.6% was achieved compared to the sole steel counterpart. This was related to an intact adhesion at the carbon fibre–steel interface after roll forming, which allowed the carbon fibre patch to effectively absorb the deformation energy. The results suggest that roll forming presents a low-cost alternative for metal hybrid part production with significant potential to reduce weight and increase the structural performance of future automotive components.

This project is supported by ARC Training Centre in Lightweight Automotive Structure (project number IC160100032) and the Ford Motor Company.

July 2022

Two new publications from the group.

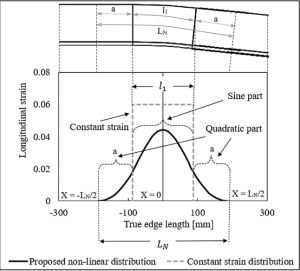

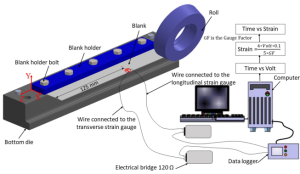

Achuth Sreenivas, Buddhika Abeyrathna, Bernard Rolfe and Matthias Weiss recently published a new paper “Longitudinal strain and wrinkling analysis of variable depth flexible roll forming” in Journal of Manufacturing Processes. Strain distribution in a flexible rollformed flange is not constant, a non-linear variable strain distribution function is required. In this paper, they proposed a semi-analytical model to represent the strain distribution in the mid-surface of the flange edge for a flexible roll-formed variable-depth component.

This new model will enable a more rapid process design and optimisation before time-consuming FEA analysis is performed. Read more …

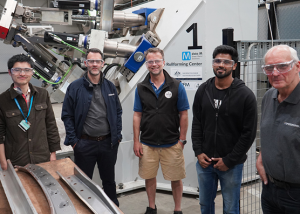

Abdelrahman Essa, Buddhika Abeyrathna, Bernard Rolfe and Matthias Weiss published a paper “Prototyping of straight section components using incremental shape rolling” in The International Journal of Advanced Manufacturing Technology. Incremental shape rolling(ISR) is a new forming technique, and this work aims at providing the frst proof of concept via experimental prototype trials. The new process is similar to some Incremental Sheet Forming (ISF) approaches but with the diference that Incremental Shape Rolling (ISR) allows the manufacture of longitudinal components from high strength metal sheets.

procedure

In this way, this work develops the platform for the development and application of ISR to form high strength and complex profles in future work. Read more…

March 2022

Improving design, manufacturability and performance

IMCRC has granted cutting-edge fire rated and acoustic panel system manufacturer, Speedpanel, and Deakin University $100,000 in funding to refine Speedpanel’s steel panel manufacturing process.

During the 10-month research collaboration, the project team will use new steel forming and joining solutions to further enhance Speedpanel’s production technology, with a focus on reducing waste and optimising and strengthening panel design. This research will also support Speedpanel’s high-volume production output and enable the business to have a more refined platform for continued expansion locally and abroad.

Commenting on the project, Lindsay Evans, Speedpanel’s Sales and Operations Manager, said the IMCRC activate funding would assist Speedpanel to further revolutionise the way it manufactures its fire-rated and acoustic systems.

“By streamlining manufacturing processes with innovative joining solutions and advanced techniques for material monitoring and process control, we’ll be able to evolve our product offering and bring a more environmentally friendly and sustainable panel system to market,” he said.

“Tapping into Deakin’s expertise in material analysis and forming process control will enable us to assess and monitor material properties and key production parameters throughout the process to enhance process efficiency, enabling better quality control and reducing waste.”

(Resource: IMCRC)

27 Sep. 2021

Two PhD postions with scholarship (~AUD 29,000 p,a.) and other benifits* provided.

For more information, please refer to project description link below.

Project 1: Micro-forming titanium foil to improve costs and performance of hydrogen fuel cells

Project 2: Giving new life to scrap metals by advanced manufacturing

July 2021

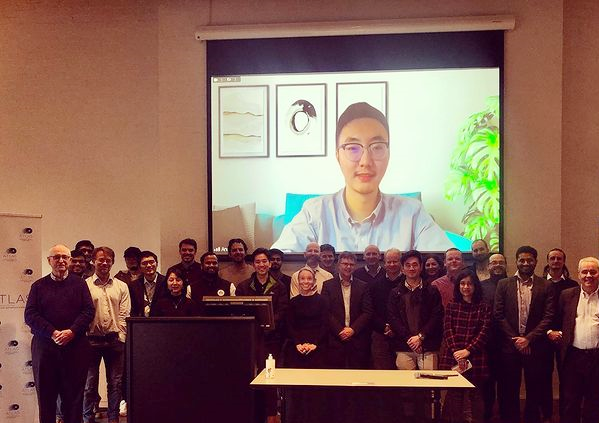

ATLAS (ARC Training Centre in Lightweight Automotive Structures) All Hands Workshop was held at Workshop at Waurn Ponds Estate, Deakin University. Post Docs and PhD students of the ATLAS Program presented their research project updates at the Workshop. Due to the pandemic, this is the first face-to-face workshop held in 2021. Three keynotes speakers were invited: John Jaranson from Ford Motor Company USA, Chris Wong from Department of Transport Victoria and Prof. Matthew Barnett from Deakin University.

(Credit: Cara)

November 2020

New publication

Dr Shiromani Gangoda Desinghege, Prof. Peter Hodgson and Dr Matthias Weiss have a new paper on “Microstructure effects on the material behaviour of magnesium sheet in bending dominated forming “ in Journal of Materials Processing Technology . In this paper, crystal (C-axis) orientation of magnesium sheet was controlled by cutting sheets from a hot rolled block. Combined with heat treatment to produce different conditions for grain size and material strength this enabled for the first time to separately analyse the effect of material strength, grain size and C-axis orientation on the springback of AZ31 sheet metal. Pure and V-bending tests were performed and combined with advanced Digital Image Correlation (DIC) to experimentally determine the neutral layer shift for different levels of outer fibre bending strain before and after springback. Read more

August 2020

New publication

Dr Yong Sun, Yixin Duan and Dr Matthias Weiss along with collaborators from Australian Nuclear Science Technology Organization (ANSTO), University of Newcastle and Baosteel have a new paper on “Forming-Induced Residual Stress and Material Properties of Roll-Formed High-Strength Steels “ in Automotive Innovation. This paper investigates the forming-induced longitudinal residual stress and material property variation in a roll-formed high-strength MS1180 automotive rocker panel. The finite element analysis results for residual stress are validated by neutron diffraction measurements. It is found that the flower design, in particular the overbending stages, play a significant role in the formation of residual stress and the change in material properties. Read more