Ivan Hu’s PhD project

The formability of roll-forming carbon fibre reinforced metal hybrid (CFRMH) components

PhD Candidate: Xinyu Hu

Aim:

To find Roll-Forming based solutions for manufacturing the automotive structural components of Carbon Fibre Reinforced Metal Hybrid (CFRMH), focusing on saving body weight, lowering the costs, enhancing the output rate and the component performance in static and crash tests.

Background:

Roll-forming based solutions make full use of the advantages of traditional manufacturing process like lower tooling costs while higher material utilization and output rates. With these excellent performance, roll-forming technique is frequently and commonly used at some automobile manufacturers to produce some long structural and collision components. As a result, roll-forming is well known as an economical and efficient manufacturing approach in the automobile industry. As for the CFRMH material, it is anticipated to combine the both advantages of two dissimilar materials (Carbon Fibre Reinforced Composites and Sheet metals). Thanks to the excellent strength with low weight, this kind of hybrid material plays a more and more significant role in varieties of engineering applications across aerospace and automobile industries. CFRMH materials gradually replace the mono-metals in some specific fields with reduced weight and high corrosion and temperature resistance. This study will assess the value of Roll-forming CFRMH components, and will scientifically design, optimize the manufacturing process while predicting the potential occurrence of defects and failures during this process.

Methodology:

At stage 1, to manufacture the preforms, metal sheet raw material, CFR-PA6 and the adhesive film will be fabricated by hot press machine. At this time, there will be an investigation on the effect of process parameters (temperature, holding time and pressure), metal surface treatment and adhesive strength. At stage 2, some mechanical performance will be investigated by simple 3-point roll bending, while a mathematical analytic model will be constructed. Then, through combining the theoretical model, advanced simulation and experiment method, the springback mechanism will be studied. Afterwards, the forming limit of CFRMH (pre-cured, post to forming and fully cured condition) will be analysed based on the failure modes after roll-bending. Using SEM can observe the fracture of fibre and matrix and delamination. At stage 3, after the analysis of CFRMH’s formability, the optimized process design will be conducted for manufacturing the hybrid material components with IFM’s flexible forming facility. Meanwhile, a numerical analysis will be conducted as a proof of concept. Similarly, there will come up with some prediction methods for delamination and springback issues after roll forming. (For pre-cured and full cured condition). At stage 4, there will be structural and crash tests to link post-forming adhesion strength and part performance. Finally, the business case or potential pathways will be developed to industrialize some products.

Previous Findings:

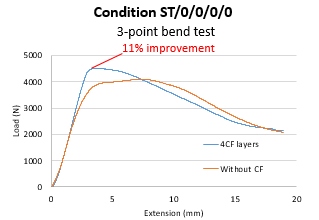

A double-hat box structure was fabricated by CDRMH material system (Steel////). Through 3-point bending test, it was found that CFRMH can improve the mechanical performance by 11% in comparison with that of mono-mild steel. Therefore, it proved that it might be feasible to structural strength by using CFRMH material.

Figure 1 Load – Extension curve in 3-point bending

Contact:

Xinyu (Ivan) Hu

Institute for Frontier Materials (IFM)

Deakin University, Geelong

Email: [email protected] / [email protected]