3D Printed Agglomerate Breakage

The breakage behaviours of multi coloured agglomerates under quasi-static compression in an Instron were analysed as a function of bond strength (by varying the polymer used to print the bonds), loading rate (x-y mm/s) and loading directions. The strain distribution was then plotted for the the random sphere agglomerate structure as a function of these variables. In addition, agglomerate structures with designed internal macro-voids in different positions and sizes were also created and their breakage behaviour analysed an effort to better understand parameters governing the mechanical properties of agglomerates with cavities and voids. Step by step procedure of how to make these agglomerates can be found here. Overall the results demonstrate a new technique to understand agglomerate deformation and breakage, including due to defects and cavities, which is an inevitable process during particle handling in industry but poorly understood at present.

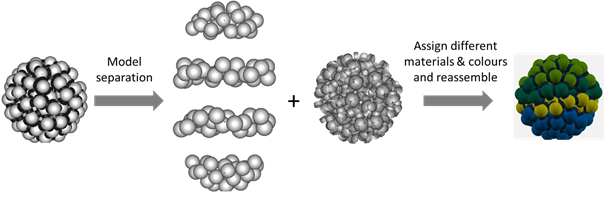

Figure. Manipulation process of the agglomerate CAD model into assemblies and the final design to be 3D printed

Binder jetting of well-controlled powder agglomerates for breakage studies

This work is done by our superstar women in STEM post-doc, Dr Jun Zhang!

Click on the link above to read about how Binder jetting 3D printing of powder granules can be used to control geometry and strength.